- Vertical machines

- Vertical packaging machine PT4

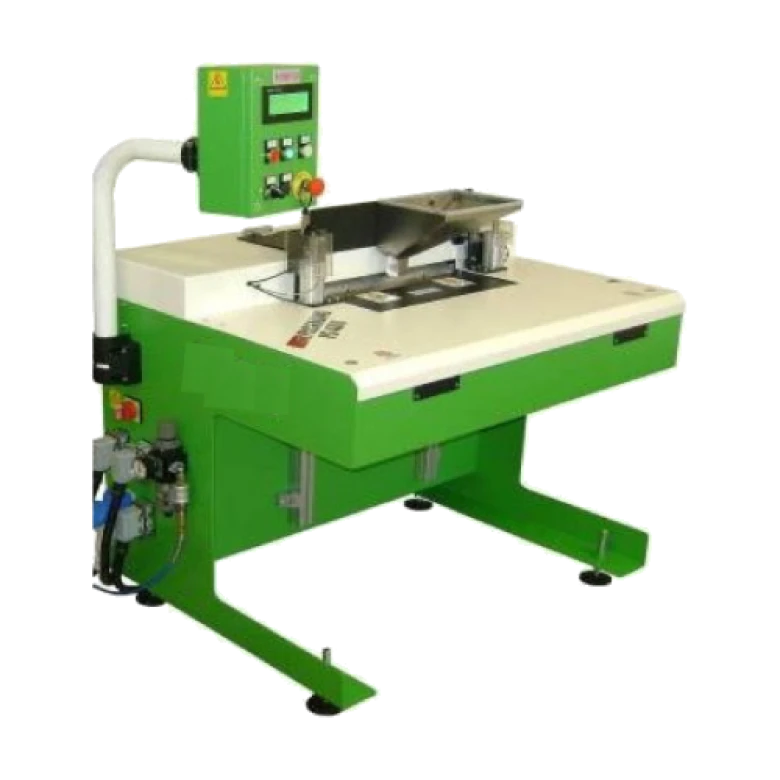

Vertical packaging machine PT4

It is a machine designed to form polyethylene bags in various sizes without vertical welding using PE tubing. The packaging machine consists of a sturdy steel structure that is carefully welded, treated and powder coated, mounted on height-adjustable feet or with self-locking wheels to facilitate movement.

Technical features:

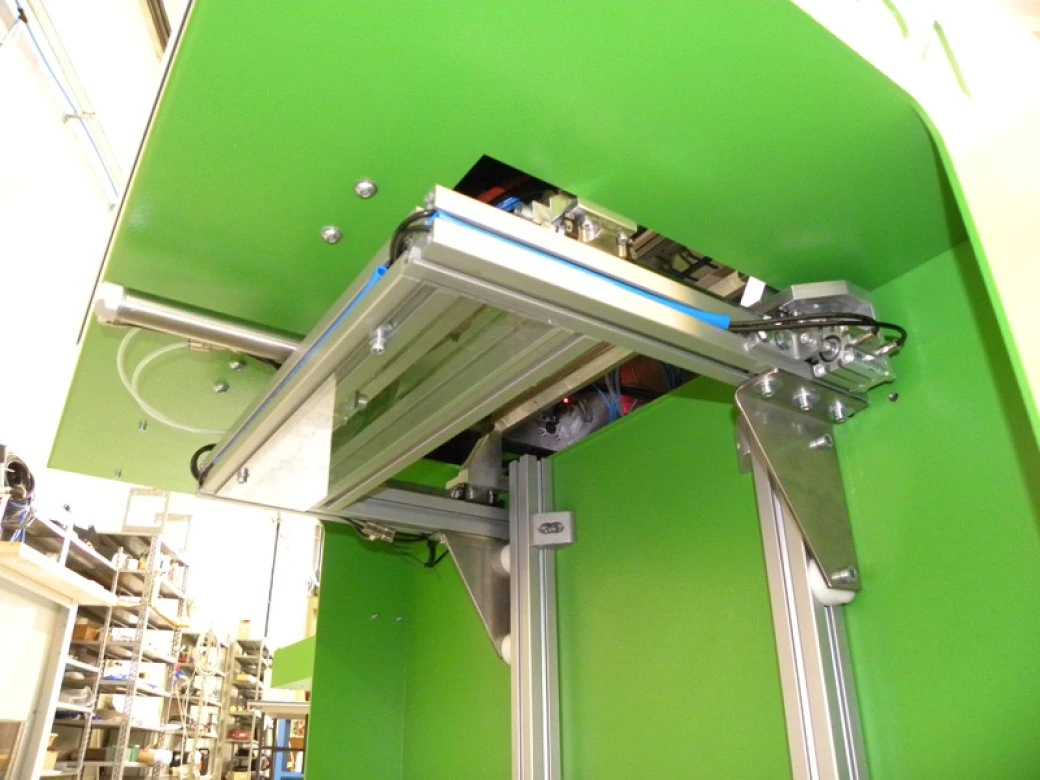

The tubing reel is housed on a special shaft and guided by adjustable cones to ensure the film is centered. The polyethylene is dragged by special counter-rotating antistatic rubber rollers, moved by brushless motors, appropriately treated to facilitate loading into the machine and unwinding the film to size for the work cycle. The bag is formed to the length set by the panel, sectioned by a pneumatic cutting movement with a shaped blade and opened by a flap suction system combined with a mechanical cam movement. The safe and patented opening system, combined with a set of adjustable clamps, guarantees the seal of the open bag. The clamps are adjustable and interchangeable for the entire width of the film.

The tubular welding is suitable for creating the bag and is carried out using a nickel-chromium Teflon-coated plate that is thermoregulated and timed to control the welding time and the relative cooling. The opening and closing movement of the bag is driven by brushless motors and cemented recirculating ball screws.

Filling is facilitated by a special hopper that is positioned inside the open bag and, once the loading is complete, the funnel rises to start the closing cycle; the welding cycle can be started by a button on the control panel, by a pedal or by a cyclic time pre-set from the panel. All the machine setting and adjustment parameters are easily adjustable from the Touch Screen panel.

It is possible to integrate:

the system with multiple loading hoppers and multiple tubes to increase the production speed of the machine (double bag), with a system for creating a Europa hole and an anti-choking hole, a printer and applicator for self-adhesive labels as well as a direct thermal transfer printer on film, suitable for creating customization logos and bar codes.